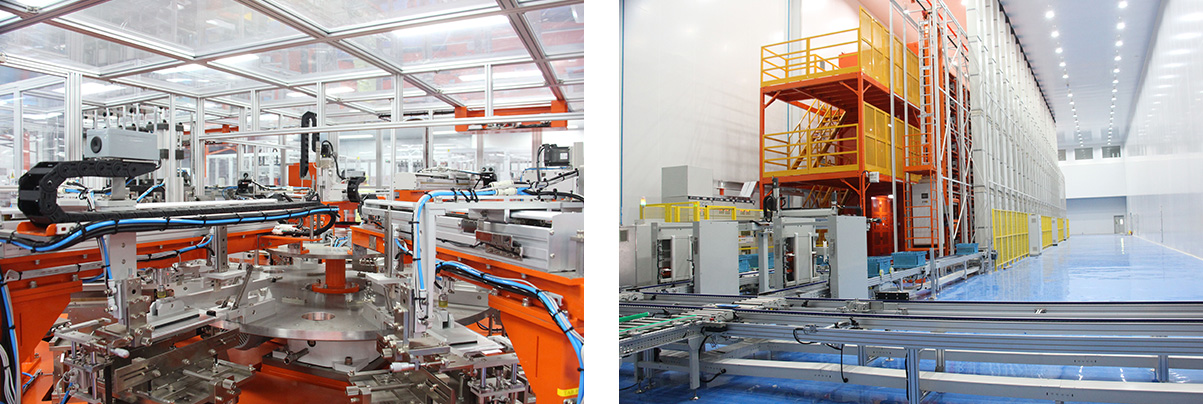

Teamgiant Shunde 8 billion Wh New Energy Vehicle Soft Pack Power Intelligent Manufacturing Industrial Park's power PACK production line is the first fully automated PACK production line for soft pack power batteries in China. System modularization, assembly informationization, diagnosis visualization, safety quantification and after-sale digitization are the design standards of the production line, which can fully realize the "intelligent manufacturing" of power battery products.

The project introduces four fully automated production lines with world-class advanced technology level, including negative ultrasonic welding machine, positive ultrasonic welding machine, aluminum-plastic film assembly machine, battery feeder, feeder, etc. It has 1472 sets of advanced equipment including domestic pulping machine, extrusion coating machine and high-speed die-cutting machine, and constructs an annual 8GWh triple soft-packed lithium-ion power battery project.

Foshan Teamgiant New Energy Technology Co., Ltd. has used fully automated equipment in the selection of manufacturing equipment, such as high-efficiency automatic core production, high-precision manufacturing control, intelligent on-line detection, and full-line automatic material production scheduling logistics system. Combining digital MES and WMS management and control system, it has truly realized intelligent manufacturing and become the most advanced automated manufacturing benchmark in the industry.

Battery fabrication from raw materials of stirring system to the downline of finished batteries realizes high efficiency and full automation production process.